Numerical Prediction Of Cavitation In Pumps

Numerical Prediction Of Cavitation In Pumps

ABSTRACT

With the increase in power per unit of volume for modem pumps, driven by manufacturing

costs reduction, cavitation becomes more arid more the main limiting factor in pump

design. The classical one-dimensional design rules applied for decades are no longer

sufficient, and for this reason, there is a strong need for more accurate

numerical tools to predict the cavitation behavior of pumps.

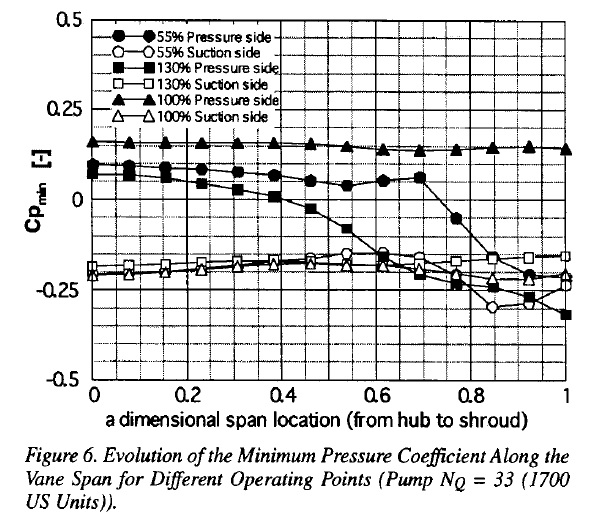

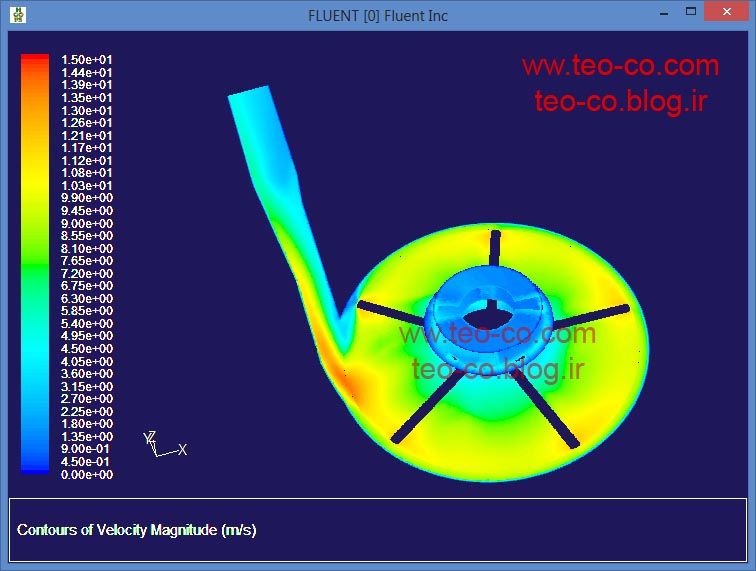

An original cavitation prediction method is presented and its results are

compared to experimental data for five pumps of specific speeds from 15 to 125

(775 to 6500 US units). The numerical method introduced in this paper for the

prediction of the cavitation development in pumps is a simplified version of a

previously developed program successfully used in similar cases. Motivation for

this simplification was to allow the program usage during the design process of

suction impellers. The accuracy of this simplified method as well as its usage

as a design tool is discussed.

Download Link:

![]() Numerical Prediction Of Cavitation In Pumps

Numerical Prediction Of Cavitation In Pumps

حجم: 687 کیلوبایت